7075-T6 The Backbone of Performance

In the realm of AR-15 customization, the materials chosen for rail accessories are pivotal. The use of 7075-T6 aluminum stands out as a superior choice, offering unparalleled strength and durability. At RailScales, we prioritize this material to ensure our products not only meet but exceed performance expectations.

What is 7075-T6 Aluminum?

7075-T6 aluminum is a high-strength alloy renowned for its exceptional properties. Originally developed for aerospace applications, it combines zinc as the primary alloying element, resulting in an alloy that boasts impressive strength and resistance to fatigue.

Is 7075-T6 Stronger Than Steel?

While steel is traditionally viewed as the benchmark for strength, 7075-T6 aluminum offers a remarkable strength-to-weight ratio. In certain applications, it approaches the tensile strength of some steels but at a fraction of the weight, making it ideal for applications where both strength and weight are critical factors.

Advantages of 7075-T6 for Firearm Accessories

- High Strength-to-Weight Ratio: Provides robust durability without adding unnecessary weight.

- Excellent Fatigue Resistance: Ensures longevity even under repetitive stress conditions.

- Corrosion Resistance: Offers resilience against environmental factors, especially when properly anodized.

7075-T6 vs. 6061 Aluminum

While both 7075-T6 and 6061 are popular aluminum alloys in firearm manufacturing, they have distinct differences:

• Strength: 7075-T6 has a higher tensile strength compared to 6061, making it more suitable for high-stress applications.

• Machinability: 6061 is easier to machine and is often used for components where complex shapes are required.

• Cost: 7075-T6 is generally more expensive due to its superior properties and manufacturing complexities.

Is 7075-T6 Rustproof or Water Resistant?

While 7075-T6 aluminum exhibits good corrosion resistance, it is not entirely rustproof. However, when treated with Type III hardcoat anodizing, its resistance to environmental factors is significantly enhanced, making it well-suited for firearm applications.

RailScales Products Utilizing 7075-T6 Aluminum

At RailScales, we incorporate 7075-T6 aluminum in several of our premium products:

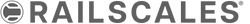

• QTR™ Stop: Designed as a lightweight solution to prevent shooters from slipping a hand in front of the muzzle, and filling the side gaps up to the rail to prevent heat exposure from muzzle blasts.

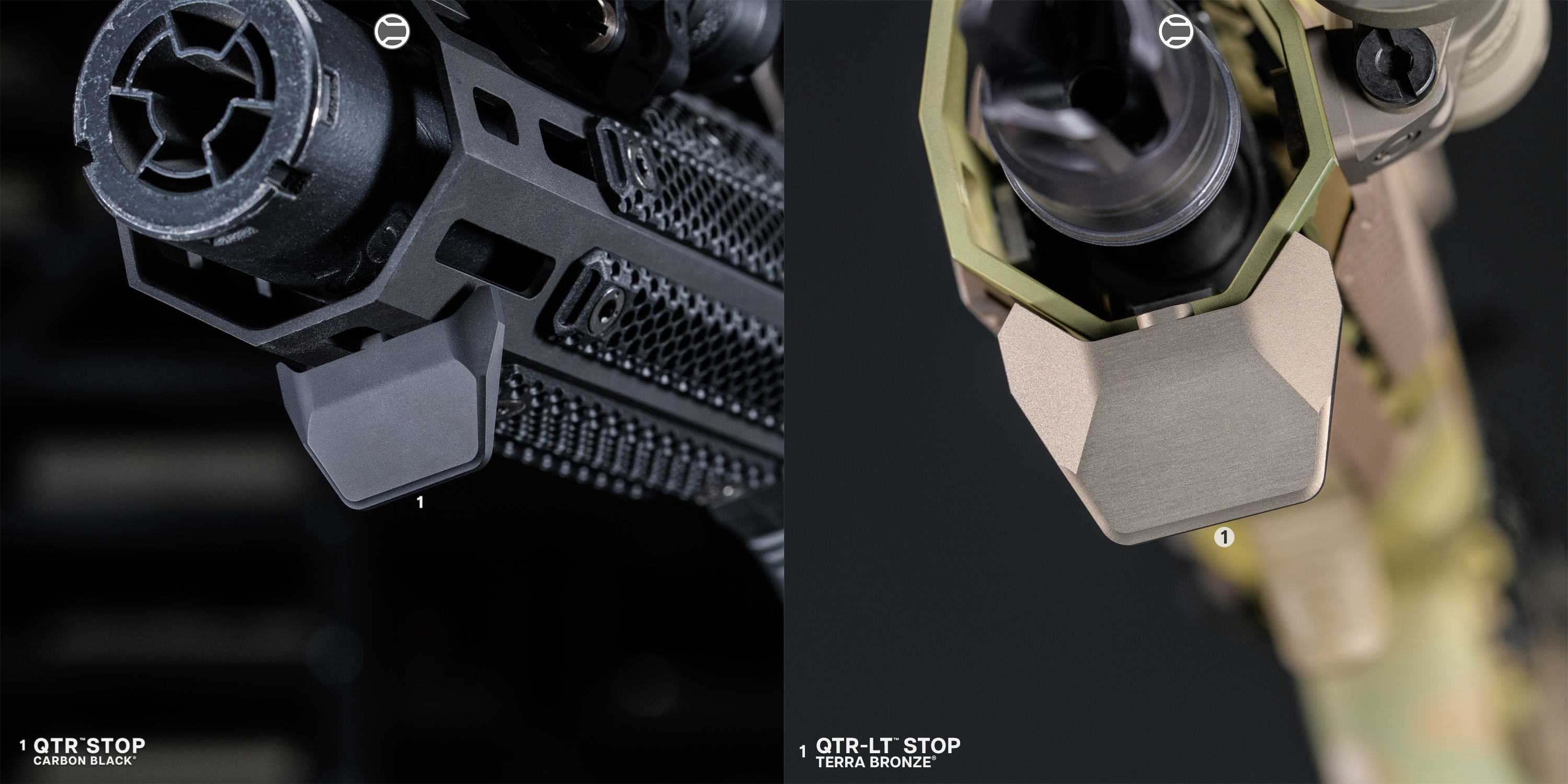

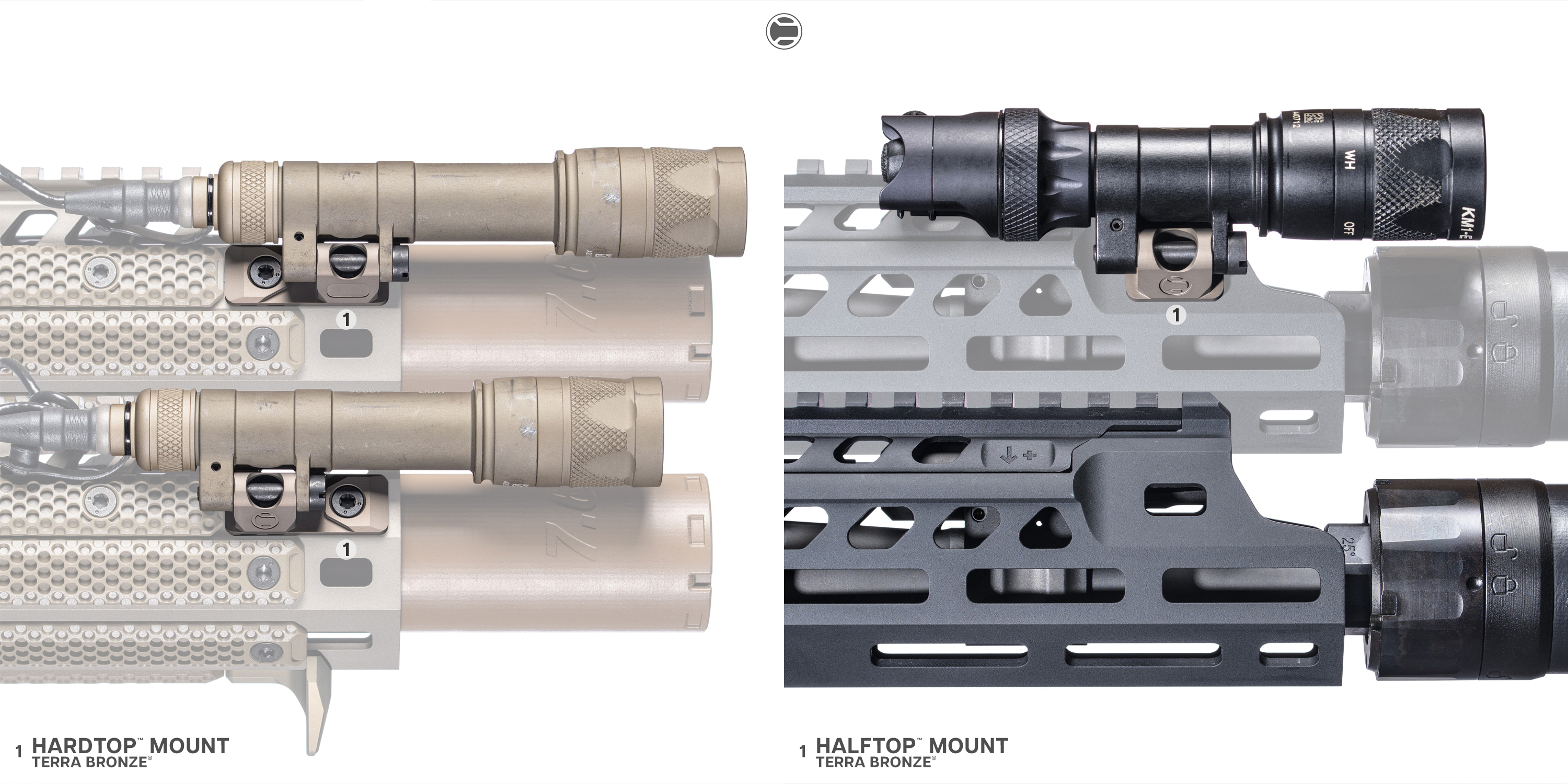

• Halftop™ & Hardtop™ Light Mounts: Engineered for optimal light placement, these mounts offer robust performance without adding bulk.

Each of these products is available in anodized finishes such as Carbon Black® and Terra Bronze®, ensuring both aesthetic appeal and enhanced surface protection.

Choose Wisely, Build Intelligently

Selecting the right materials for your AR-15 accessories is crucial for achieving optimal performance and longevity. By choosing products made with 7075-T6 aluminum, like those offered by RailScales, you're investing in quality, durability, and reliability.

FAQ: Understanding 7075-T6 Aluminum in AR Rail Accessories

Q: What makes 7075-T6 aluminum superior for firearm accessories?

A: 7075-T6 aluminum offers exceptional tensile strength while remaining lightweight. This makes it ideal for firearm components like rail accessories that are subjected to repeated stress, impacts, and temperature fluctuations. It holds tighter tolerances and resists deformation better than most other alloys.

Q: Is 7075-T6 aluminum used in military-grade firearms?

A: Yes. 7075-T6 aluminum is commonly used in military and aerospace applications due to its strength-to-weight ratio and resistance to fatigue. It's the same grade of aluminum used in many MIL-SPEC AR-15 upper and lower receivers.

Q: Will 7075-T6 aluminum rust or corrode over time?

A: While aluminum doesn’t rust like steel, it can corrode. However, when anodized properly (like RailScales' Type III hardcoat anodizing), 7075-T6 becomes significantly more resistant to corrosion, wear, and abrasion, making it extremely durable in harsh environments.

Q: How does 7075-T6 aluminum compare to 6061 aluminum?

A: 7075-T6 has nearly twice the tensile strength of 6061 and is much harder, making it better suited for components that endure mechanical stress. While 6061 is easier to machine and slightly more corrosion-resistant in raw form, 7075-T6 wins in high-performance, high-wear applications.

Q: Is there any downside to choosing 7075-T6 over 6061?

A: The primary drawback is cost. 7075-T6 is more expensive and harder to machine, which can raise manufacturing costs. However, for users prioritizing strength, precision, and long-term durability, the benefits outweigh the price.

Q: Why does RailScales choose 7075-T6 aluminum for some of its accessories?

A: RailScales chooses 7075-T6 because it aligns with our commitment to precision, durability, and performance. For mission-critical parts like the LEAF™ Fixed Sights and Halftop™/Hardtop™ Light Mounts, this alloy offers unmatched structural integrity without adding unnecessary weight.

Q: Are there any color limitations with 7075-T6 aluminum?

A: Not at all. In fact, RailScales uses 7075-T6 for anodizing premium finishes like Carbon Black® and Terra Bronze®, which not only add a custom look but also further protect the surface.

RailScales 7075-T6 Product Highlights

The QTR™ Stop offers a precision-engineered barrier to keep hands clear of the muzzle while sealing side gaps from blast heat; Halftop™ and Hardtop™ Light Mounts redefine weapon light control with rock-solid, pressure-tested M-LOK integration; and the MonoLift™ Riser, forged from 7075-T6, elevates optics for cleaner sight lines and uncompromising durability.

QTR™ Stop

Designed as a lightweight solution to prevent shooters from slipping a hand in front of the muzzle, and filling the side gaps up to the rail to prevent heat exposure from muzzle blasts.

Halftop™ and Hardtop™ Light Mounts

Industry-leading weapon light mounting solutions for M-LOK rails, offering stability and adjustability under pressure.

MonoLift™ Riser

Built with 7075-T6, this optic riser enhances sight alignment, posture, and optic durability for the most demanding shooters.

Disclaimer:

This blog content was generated by a human and with the aid of artificial intelligence. It may contain errors or inaccuracies and should not be relied upon as a substitute for professional advice. This content is for SEO/entertainment purposes only and the views expressed in this content does not necessarily reflect the views of RailScales LLC. For more information, please refer to bullet point #13 on our FAQ.