For firearm enthusiasts, there are certain rites of passage.

For instance, there is the first time you purchase a new gun, and the first time you fire it. There’s the first time you have a major malfunction on the range, and the first time you have the skills to address it. For the AR-15 crowd, one of the key moments in your firearm career is taking the time to build your very own AR-15.

AR 15 Build Tool Kit

Thanks to the huge number of specialty parts and AR accessories on the market, it’s easier than ever to assemble your own AR-15. While many spend hours of time researching and selecting each individual component for the rifle, very few spend any time thinking about what tools they’ll need to acquire in order to actually assemble the rifle.

The fact of the matter is, the simple toolkit you keep stashed the back of your closet or tucked away somewhere in your garage simply isn’t enough to adequately assemble your rifle with any surety that it will work later. To make sure your first or next project goes smoothly, RailScales has assembled this list of AR 15 build tips on what tools you should have before you begin building your next rifle.

Designate a Workspace

Before you rush out to buy new tools or even new parts, it’s important to ensure that you have enough space to actually work on your project. We’re sure that many AR 15’s have been built in kitchens or bedrooms throughout the country, but having a designated workspace makes the process easier and less stressful.

If possible, designate a space in the garage and set your workbench there. Having a clean, focused area to work in can make the process go much more smoothly on top of making it much less likely for you to lose any parts. However, if space is at a premium in your garage, try and section off a space in your home specifically for building and modifying your guns.

Building Your Toolkit

Like all major projects, you get what you pay for when it comes to the tools you use. When possible, get the best quality tools that you can afford. Using higher-quality tools often leads to higher quality results and fewer headaches when you first take your rifle to the range.

Of course, you don’t have to break the bank paying for tools to build a nice looking AR. Simply purchase what you can afford at the time and make upgrades when you can!

Bench Vise

One of the reasons you need a cordoned off space to work is because you need a table or platform durable enough to fit your bench vise. That’s because you’ll find that your bench vise becomes your closest ally during the AR-15 building process.

Securely mounting the vice to your workbench or work surface will improve serve as an extra hand during your build. The bench vise will be invaluable as you mount major and minor parts to both your upper and lower receivers. It’s also nearly impossible to torque a barrel nut or fit castle nuts onto your upper receiver without one. At a minimum, you want a vise with a jaw size of at least 4 inches.

In addition to your bench vise, you’ll want a Weisbach kit. These blocks are specifically designed to hold your AR in place through the mag well while you’re working on it. Typically, vice blocks are made from high-quality polymer, but in a pinch, you can get away with a block of wood that slots into your mag well.

A Set of Punches

The AR 15 platform is known for its high tolerances and close matches between parts. This is made possible by the use of a variety of roll and punch pins. Without a set of punches for these pins, however, you can quickly mash, smash, and blunt these pieces into an unusable state.

When looking for a punch said, consider also picking up some rope and holders. These are helpful in getting the roll pin started into the receiver or component. You can follow this by using the roll pin punch. These punches feature a blunted and rounded tip that naturally centers itself in the middle of the roll pin. This prevents crushing the ends of your roll pins.

An Armorer's Wrench

Essentially the Swiss Army Knife of the AR-15 world, an armorer’s wrench is a multipurpose tool that helps you quickly assemble and disassemble your rifle. Typically you will find that this wrench can help you install barrel and castle nuts, receiver extensions, and even place flash hiders. Some tools even have additional features that help you open bottles, so you can have a celebratory beverage after you finish your build.

This is one tool you don’t want to skip out on, and it’s important to invest funds into high-quality armorer’s wrench. In some cases, your AR-15 may require the use of a classic torque wrench. If you don’t already own one of these tools, you can typically find one for a low price at your local hardware store or even at many thrift stores.

Ball-Pein and Brass Hammers

You should never have to forcibly strike your rifle while you’re building it, but in some cases, a few gentle love taps need to be applied in order to get the parts to seat properly. This is where a set of hammers comes in handy.

Typically, a 4-ounce or 8-ounce hammer is enough. You should also consider investing in brass or nylon hammers. These hammers are great because they are made of lightweight and soft materials that will not mar the finish of your rifle but still offer enough force to drive in a roll pin or knock out a stuck part.

Allen Wrench Set

You’ll find a variety of components on your AR-15 that make use of Allen’s head screws. Depending on where you sourced your parts, you may need a set of metric or standard Allen wrenches. In either case, it’s not a bad idea to have a set of both around as you work.

Screwdrivers and Needle Nose Pliers

These tools can be used for a variety of purposes beyond their intended use. Some AR-15 pistol grips or accessories require the use of a screwdriver to be properly mounted. In other cases, you can use a flat-head screwdriver as a small pry bar. Needle nose pliers are invaluable in managing and handling minute parts. It’s likely that you’ll find more than one purpose for each of these tools, so it’s important to acquire a large set of screwdrivers and pliers that features equipment of all sizes just in case.

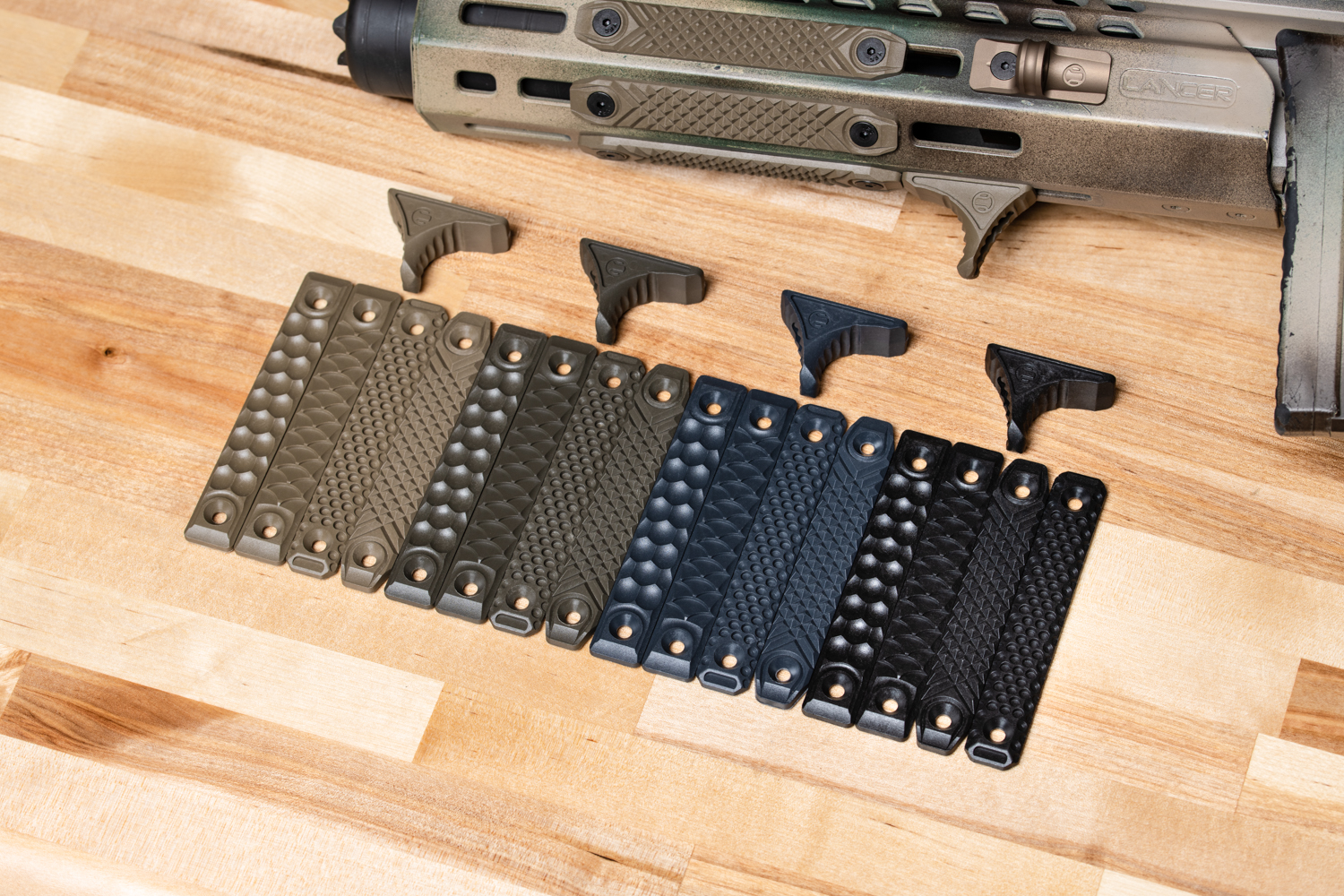

Build a Better AR with RailScales

Once you’ve assembled your workbench with all the tools outlined above, it’s time to start building your rifle. As with any project, it’s best not to cut corners on the quality of the parts your building with. That’s what you should order your AR 15 parts and accessories from Rail Scales. We use premium quality materials like HTP, G10, and machined metals to create products that effortlessly fit on your KeyMod or M-LOK handguards. We offer hand stops, forward grips, and even fixed iron sights for your next AR 15 build. Order today.

FAQ: AR-15 Build Tools and Tips

Q: Why do I need a dedicated workspace for building an AR-15?

A: A dedicated workspace ensures you have enough room to organize and work on your build efficiently. It reduces the risk of losing small parts, provides a stable surface for tools like a bench vise, and creates a safer, distraction-free environment for assembly.

Q: What is the purpose of a bench vise during an AR-15 build?

A: A bench vise acts as an extra set of hands, securely holding your upper and lower receivers while you install components. It is particularly useful for tasks that require torque, such as tightening barrel nuts and installing castle nuts.

Q: Do I really need an armorer’s wrench, or can I use regular tools?

A: An armorer’s wrench is specifically designed for assembling AR-15 rifles, featuring functions for tightening barrel and castle nuts, installing flash hiders, and more. While regular tools can work in some cases, they lack the precision and versatility of an armorer’s wrench, which could lead to issues during assembly.

Q: What are roll pin punches, and why are they important?

A: Roll pin punches are specialized tools designed to align with and seat roll pins without damaging them. They prevent crushing or deforming the pins, ensuring a secure fit and maintaining the rifle's functionality.

Q: Why is it important to use brass or nylon hammers instead of a standard hammer?

A: Brass and nylon hammers are softer than steel, which prevents damage to your rifle's finish and components during assembly. They are ideal for seating roll pins or loosening stuck parts without causing permanent marks or scratches.

Q: Are there specific tools for M-LOK and KeyMod accessories?

A: Yes, tools like Allen wrenches and torque wrenches are often required to properly mount M-LOK and KeyMod accessories. RailScales products, for example, include T20 Torx fasteners, which require a compatible tool for secure installation.

Q: How can RailScales products improve my AR-15 build?

A: RailScales offers premium accessories like M-LOK handstops, forward grips, and rail covers. These products enhance your rifle's grip, heat management, and overall ergonomics, ensuring better performance and a customized feel.

Disclaimer:

This blog content was generated by a human and with the aid of artificial intelligence. It may contain errors or inaccuracies and should not be relied upon as a substitute for professional advice. This content is for SEO/entertainment purposes only and the views expressed in this content does not necessarily reflect the views of RailScales LLC. For more information, please refer to bullet point #13 on our FAQ.