Whether you’re on the range, in competition, or relying on your AR-15 for personal defense, few things are as frustrating — or potentially dangerous — as a jammed rifle. Not only can it interrupt your flow, but it can erode confidence in your firearm when you need it most. Let’s break down the most common causes of AR-15 malfunctions, why reliability matters, and how you can use smart AR-15 accessories to limit jamming issues.

The Frustration of AR-15 Jamming During Live Fire

AR-15 jamming doesn’t just disrupt shooting — it can:

• Undermine shooter confidence

• Lead to slower follow-up shots or failed engagements

• Force unplanned and potentially unsafe clearing of the firearm

• Damage internal parts if forced open

This makes addressing reliability issues non-negotiable, whether you’re a weekend shooter or a professional.

Why Reliability is Non-Negotiable

A reliable AR-15:

• Builds shooter trust and confidence

• Supports fast, uninterrupted follow-up shots

• Reduces wear and tear from stoppages or misfeeds

• Ensures the firearm performs as designed in defensive scenarios

Most Common Causes for AR-15 Jamming

AR-15 malfunctions often stem from neglected maintenance, bad magazines, or poor-quality ammo—each inviting failures like double feeds or stovepipes. To keep your rifle running reliably, prioritize cleanliness, quality components, and proper gas system function.

Dirty or Non-Lubricated Components

Carbon buildup and friction are jamming’s best friends. Focus on:

• Bolt carrier group (BCG)

• Chamber and barrel extension

• Gas rings

• Extractor and ejector

A dry or carbon-caked rifle invites stovepipes, failures to eject, and double feeds.

Faulty or Worn Magazines

Magazines are the #1 overlooked cause of malfunctions. Look for:

• Bent feed lips

• Weak or worn magazine springs

• Cracked polymer or damaged metal bodies

Always test new mags before relying on them in the field.

Cheap or Improperly Sized Ammo

Not all ammo is created equal. Watch out for:

• Out-of-spec cases

• Underpowered loads that can short-stroke the BCG

• Excessively dirty ammunition fouling the chamber quickly

Gas System Issues

The AR-15 runs on gas. Problems here can kill reliability:

• Gas block alignment

• Worn gas rings

• Leaky gas key

• Undersized or oversized gas ports depending on the build

Inferior or Worn Internal Parts

Cut corners on parts, and you’ll pay for it in jams:

• Weak extractor or ejector springs

• Rough or incorrectly sized chamber

• Soft metal in critical components like the bolt or cam pin

How Accessories Can Reduce Jamming Risk

High-quality AR accessories not only improve performance — they can prevent jams before they start:

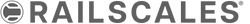

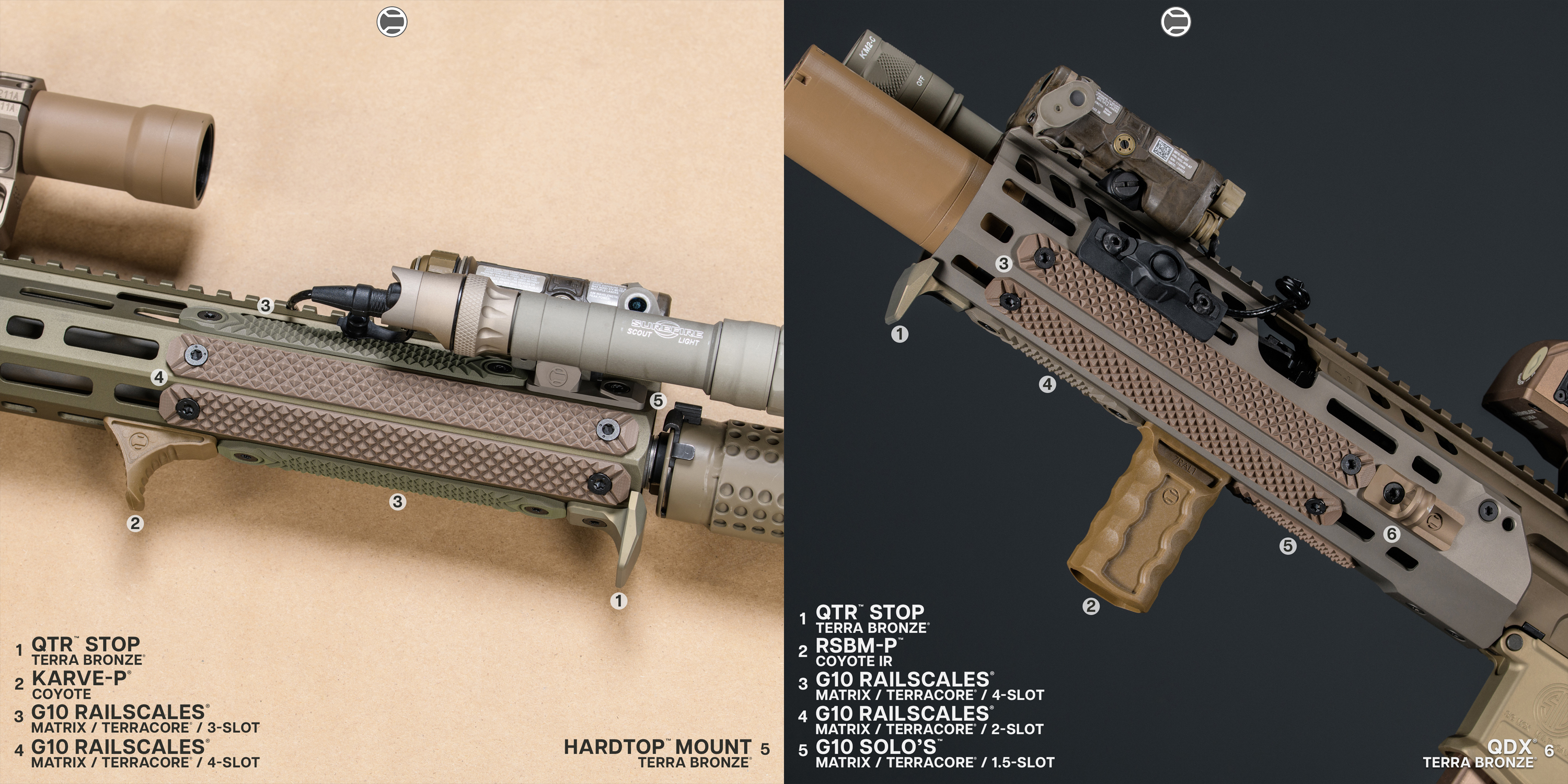

• RailScales Handguards + Covers → Keep your support hand cool, so you stay in control during clearing drills.

• Karve® Handstops or Anchor® Vertical Grips → Improve indexing and control, reducing the chance of inducing malfunctions with poor grip.

• CSMR® Mag Release Button → Smooth, confident mag swaps eliminate hesitation when replacing faulty mags.

• LEAF® Sights + Light Mounts → Free up rail space for critical accessories without adding snag points that can interfere with function.

Must-Have Accessories for Reliable Firing — Every Time

If you want your AR-15 to run like a sewing machine:

• Use high-quality magazines (PMAGs, Lancers, or metal GI mags in good condition)

• Install a quality BCG with properly staked gas keys

• Upgrade to a reliable charging handle

• Use reliable light mounts and grips like RailScales Hardtop™ + Karve®

• Apply proper lubrication every few hundred rounds, especially in suppressed setups

FAQ: AR-15 Jamming and Solutions

Q: How often should I clean my AR-15 to prevent jams?

A: Clean and lubricate the BCG and chamber every 700-1,00 rounds, or more often if running suppressed.

Q: Can magazines cause AR jams?

A: Yes — inspect feed lips, springs, and bodies regularly. Always replace worn mags.

Q: Does cheap ammo increase jamming?

A: Absolutely. Stick with brass-cased, factory-loaded ammo from trusted brands for best results.

Q: Are piston systems more reliable than DI systems?

A: In some cases, yes — especially under hard use or when suppressed. But DI systems run flawlessly when properly maintained.

Q: What RailScales products can help prevent malfunctions?

A: Handstops, vertical grips, and textured rail panels improve control, reduce heat transfer, and support better handling when clearing malfunctions.

Disclaimer:

This blog content was generated by a human and with the aid of artificial intelligence. It may contain errors or inaccuracies and should not be relied upon as a substitute for professional advice. This content is for SEO/entertainment purposes only and the views expressed in this content does not necessarily reflect the views of RailScales LLC. For more information, please refer to bullet point #13 on our FAQ.